Professor Hung-Wei Yen from the Department of Materials Science and Engineering at National Taiwan University, along with Professor Julie Cairney from the University of Sydney and Professor Hao Chen from Tsinghua University, formed an international research team to develop material strategies for steel to resist hydrogen embrittlement. Their research findings were published in Nature Communications.

In metallic structural materials, the presence of hydrogen atoms at levels as low as parts per million by weight (ppmw) can lead to catastrophic failure during service. This phenomenon, known as hydrogen embrittlement (HE), occurs due to hydrogen diffusion, which induces microcracking and rapid propagation of cracks in load-bearing steel materials. As the global trend shifts towards net-zero carbon emissions, hydrogen is expected to become a crucial energy source, but the occurrence of hydrogen embrittlement poses significant risks. Therefore, mitigating hydrogen embrittlement has become a pressing global concern.

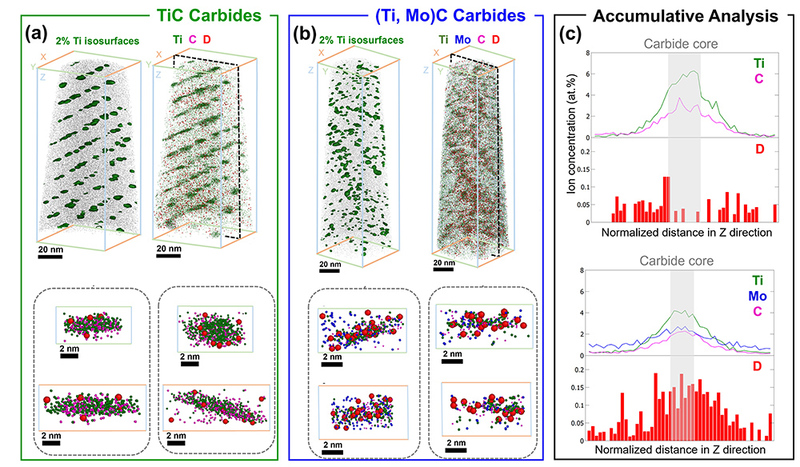

Mitigating hydrogen embrittlement has been a longstanding challenge for mankind. In material design strategies, creating special microstructures to act as hydrogen traps to limit hydrogen diffusion is an important approach to suppressing hydrogen embrittlement. Titanium carbide (TiC) nanoparticles are typical hydrogen traps in steel, having been used for over 20 years. However, their effectiveness in suppressing hydrogen embrittlement remains limited. The research team first confirmed through first-principles calculations that vacancies in carbides serve as effective hydrogen traps, inhibiting hydrogen diffusion in steel. To verify this concept, the team developed advanced high-strength steel with precipitated nanoparticles of TiC and (Ti, Mo)C at the interfaces. However, detecting trace amounts of hydrogen distribution in nanostructures posed a significant challenge. The research team developed an atom probe tomography (APT) technique using deuterium as a substitute for hydrogen to successfully resolve the carbon vacancy concentration and hydrogen trapping characteristics of the nanoparticles. The research findings revealed that the composite (Ti, Mo)C had a higher carbon vacancy concentration and could trap hydrogen atoms in carbon vacancies within the carbide crystals, while typical TiC could only trap hydrogen atoms at carbide interfaces. Therefore, the composite (Ti, Mo)C exhibited higher hydrogen trapping capacity than TiC. In materials engineering, the substitution of Mo2+ ions for Ti4+ ions in TiC carbides to create carbon vacancy defects is a key aspect of carbide crystal defect engineering, serving as a strategy for steel materials to resist hydrogen embrittlement and representing an important achievement in NTU's research on net-zero carbon emissions.

Professor Hung-Wei Yen has been researching interface precipitation of carbides in steel for over 15 years. Since 2016, he has been conducting research on hydrogen embrittlement. He has collaborated with Professor Julie Cairney under the USyd-NTU Partnership Collaboration Award (now NTU-USyd Ignition Grants) for many years. Both parties have jointly published multiple papers on composite carbides and hydrogen traps in Acta Materialia, Scripta Materialia, and Materials & Design journals. This research achievement is the culmination of long-term collaboration, covering theoretical calculations, material design, and forward-looking analysis and detection, representing an important outcome of NTU's long-term involvement in international interdisciplinary collaboration.

Full research article: https://www.nature.com/articles/s41467-024-45017-4

來源: https://www.ntu.edu.tw/spotlight/2024/2253_20240403.html