Silicon is an attractive negative electrode (anode) material for future lithium-ion batteries because it can store much more energy than the graphite used today. However, silicon expands and shrinks dramatically during charging and discharging. This repeated swelling causes the battery electrodes to crack, lose contact internally, and degrade quickly, which severely limits battery lifetime and safety.

A new study, published in the Chemical Engineering Journal, developed a simple coating to protect silicon–graphite composite anodes. The coating is made from a common polymer (PVDF) mixed with tiny magnesium oxide (MgO) particles and can be applied using standard industrial processes.

An important discovery is that the timing of applying the coating—before the electrode is mechanically compressed during manufacturing—is critical for achieving good performance. Batteries made with the optimized coating lasted far longer than uncoated ones. Even after hundreds of charge–discharge cycles, the coated batteries retained most of their original capacity and operated very efficiently. In contrast, uncoated batteries lost performance much earlier. The coated electrodes also performed better during fast charging and discharging.

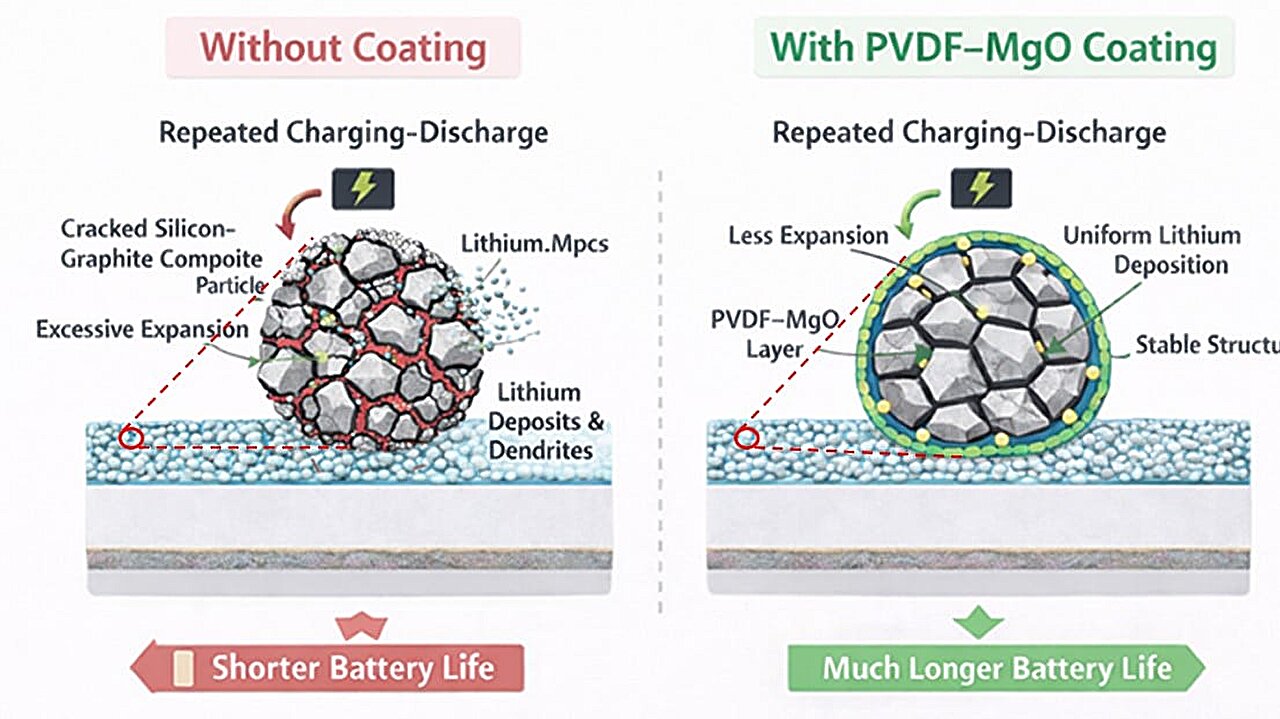

Microscopic observations explain why the coating works. Without protection, silicon electrodes expand excessively and develop cracks and internal damage. The PVDF–MgO coating significantly reduces this expansion, keeps the electrode structure intact, and maintains good electrical contact. In addition, the MgO particles help control how lithium moves and deposits inside the battery, reducing the risk of dangerous lithium buildup.

"This work shows that a simple, low-cost coating—applied at the right stage of manufacturing—can greatly improve the lifespan, reliability, and safety of high-energy lithium-ion batteries. The approach is practical and compatible with existing battery production methods, making it promising for real-world applications," says co-corresponding author Nae-Lih Wu, Ph.D., distinguished professor of chemical engineering at National Taiwan University.

To see article on TechXplore: https://techxplore.com/news/2026-01-simple-coating-high-energy-li.html